Sequencing Batch Reactors (SBR) are widely used for biological treatment of municipal and industrial wastewater. SBR’s are adaptive to variable influent feed concentrations. They typically operate in a cyclic sequence of batch reaction phases — both aerobic and anoxic.

The cycle times are programmed based upon influent conditions and adjusted periodically to insure complete treatment is accomplished. However, their operations are seldom optimized through automation on a cycle by cycle basis. The plant under consideration is fed by influent hauled in trucks from different collection sites, and experiences considerable variations in feed characteristics.

APRICOT™ by IntelliFlux was installed on a customer’s 15,000 m3/day capacity SBR as an automation retrofit to optimize the treatment performance and increase the throughput of the system. IntelliFlux utilized the system’s inline COD, TSS, Turbidity, NO3-N2, and Dissolved Oxygen (DO) sensors.

The IntelliFlux retrofit consist-ed of installing an industrial grade edge control device (ECD) adja-cent to the PLC of the system. The installation was conducted while the plant was operational. Following the installation and commissioning, the baseline mode of operation was monitored over several cycles to assess the reaction kinetics. Following this, IntelliFlux mode control and optimization was implemented on one of the SBR tanks, while a second SBR tank was operated side-by-side in the baseline mode.

The IntelliFlux mode operation involved dynamic adjustment of several reactor settings, such as, fill level, aerobic and anoxic cycle times, DO settings, decant level, sludge wastage, as well as sludge settling time between limits specified by the plant engineers.

IntelliFlux provided a complete digitalization upgrade for the system, providing continuous remote monitoring of the reactor performance, machine learning and artificial intelligence guided control and optimization of the reaction conditions, including alarms for operators during influent quality excursions or when inline sensors required maintenance.

Application Area:

Municipal Wastewater Treatment

Customer:

EPC & Facility Operator

Location:

UAE

System:

Multi-tanked Sequencing Batch Reactor

Capacity:

15,000 cubic meters/day

Operating Since:

2019

Benefits:

Increased Throughput, Energy Savings, Reduced Maintenance

IntelliFlux improved the digitalization profile of the plant by implementing a digital twin and AI based Decision Support and Automation layer, while improving the PLC/SCADA/IoT level system integration and performance. It was the least cost and quickest option toward digitalization for the plant.

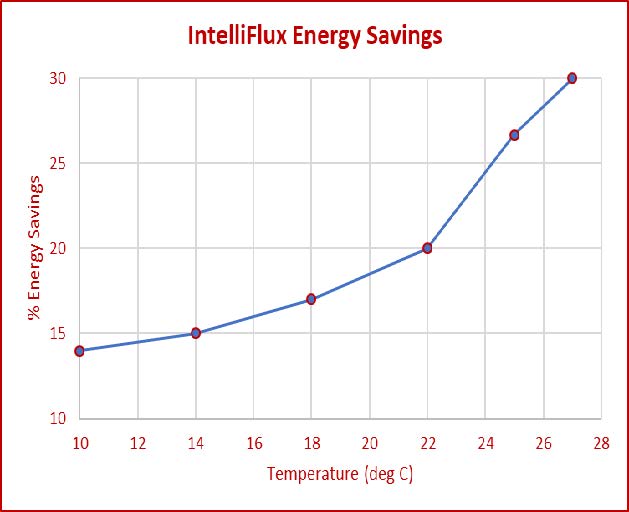

IntelliFlux operated the system in four cycles per day as opposed to three, as well as lowered the aeration times and intensities in 60% of the cycles, giving up to 45% savings in energy per cycle and an increase in the daily plant throughput by 28% over baseline. The energy savings alone amounted to $2,450 per month.

IntelliFlux adjusted the reactor settings and managed operation even in cold weather conditions, realizing energy savings and maintaining throughput without constant operator intervention.