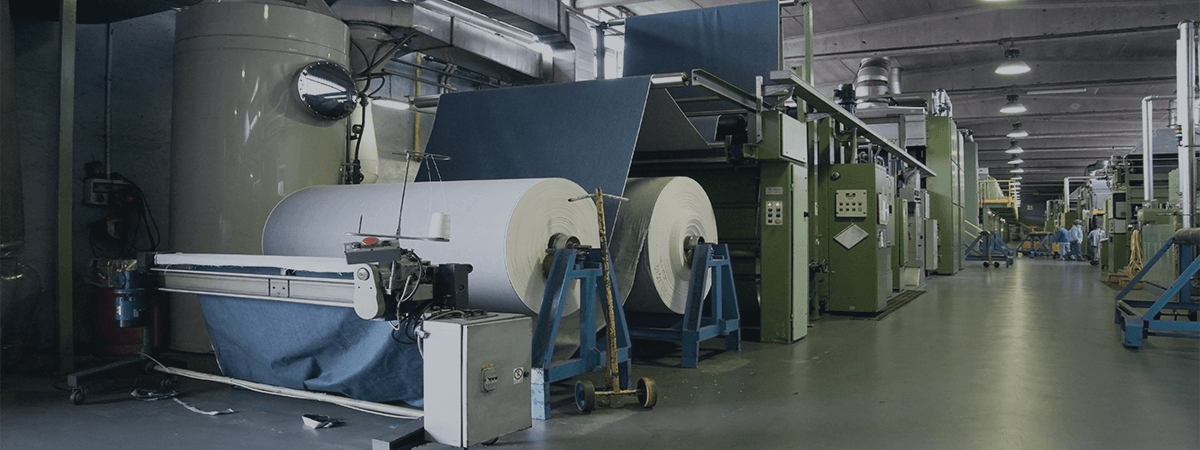

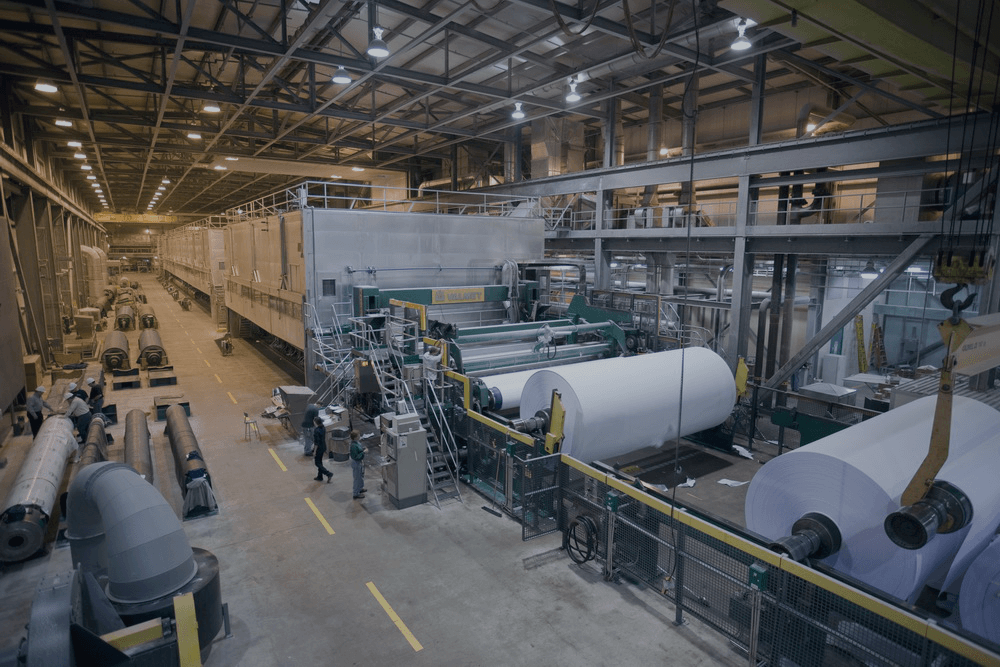

TEXTILE AND PAPER

Meeting discharge regulations and improving water footprint with Intelliflux

Challenges

Operator training, retention challenges

Continuing pressures placed upon system owners to achieve more stringent discharge and recycling objectives

Cooling tower/heat exchanger management as waste stream exits facility at high temperatures

Varying Waste Water quality with frequent high concentrations of complex dyes and tanning compounds requiring biological treatment. Metals precipitation ( Cr or Sb), Recycle systems and Membrane BioReactors with complex inhibitory compounds affecting treatment efficiency.

As highly water intensive segments of the chemical process industry, subject to scrutiny about water footprint. Push for Zero Liquid Discharge (ZLD) operations.

Zero Liquid Discharge (ZLD)

Textile processing is water intensive. Process water in textile processing plants is variable since it is sourced frequently from river waters or variable quality municipal sources. More and more dye houses are deploying on site process water and waste water treatment and reuse plants to improve water footprint.

Sustainability drives and Global responsibility in large corporations are mandating better water management practices in this industry.

Brand pressure for reduction of water used / kilogram dyed material from 400 litres to 20 or 30 litres and the pressure to achieve Brand & Industry organization (e.g. SAC, ZDHC) regulated discharge contaminant levels in wastewaters is forcing the textile industry to adopt aggressive water management and reuse strategies.

Compliance reporting and validation of discharge regulations are costly and time consuming.

IntelliFlux Benefits

Consistent and optimized operations of a single or multi unit system.

Focussed performance monitoring and process optimization backed by an understanding of process chemistries.

Consistent operations whether operating personnel change or not.

Integrate, manage, and control your water, energy and process knowldege

Improve water and energy footprint of your operations, and achieve sustainability goals.

Reporting

IntelliFlux understands the complexity of wastewater treatment in Textile Facilities. SAC, ZDHC, brands reviewing performance with respect to discharge limits – add layers of complication in your operations. It is imperative to your business to keep your system performing optimally, in compliance, while reducing both chemical and electrical usages and minimizing manpower requirements and downtime. Reporting daily, weekly or quarterly is not a problem with our customized reports generation taken from your actual plant operating data and programmed into formats you may need for Higg verification, SAC, ZDHC or your customers. Let us show you how IntelliFlux can become “Your Best Operator”.