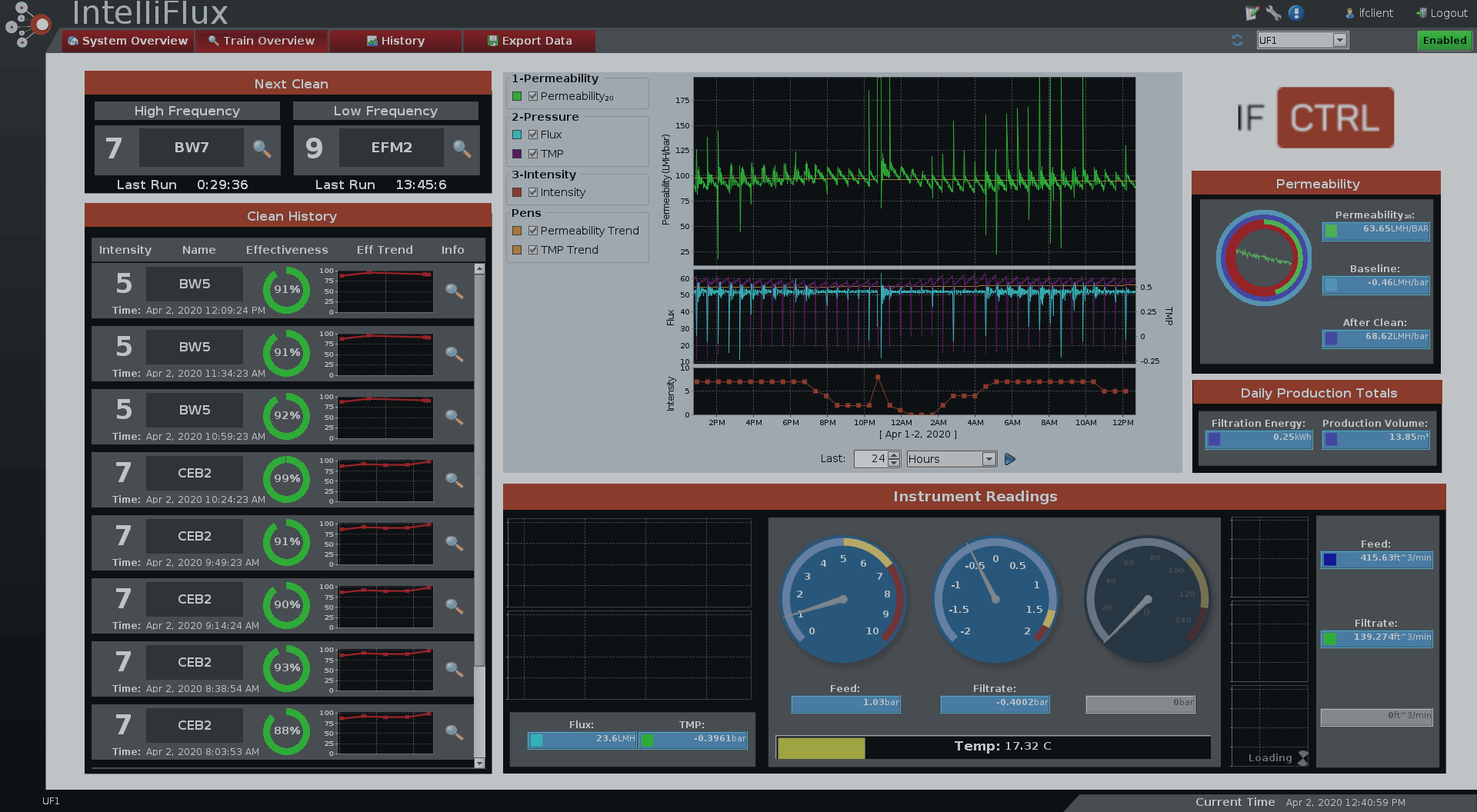

- Process monitoring & reporting

- Process analytics (utilizing DT, AI, ML)

- Self-learning process decision support

- Real-time smart plant automation

- Self-learning process optimization

- Self-learning decision automation

BEING IN CONTROL WAS NEVER SO LIBERATING...

IntelliFlux can help you transform your plant into a smart plant.

IntelliFlux can help change your asset management, reliability, and sustainability playbooks by taking a lot of your routine tasks off your plate, helping you focus on extracting more value out of your plants.

Plant Owners

Improve your plant productivity, production margins, operational reliability, and sustainability with IntelliFlux. See how the holy grail of digitalization can transform your business.

Operations Professionals

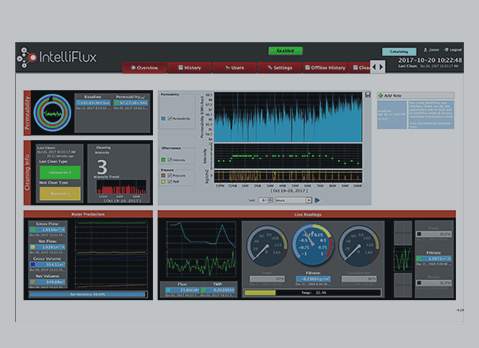

IntelliFlux virtual assistant will transform how you manage your plant. See how machine learning and predictive analytics put you in control.

Process Engineers and Managers

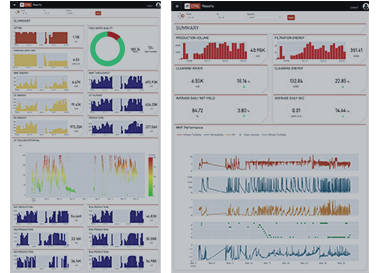

Our actionable data and analytics with digital plant surrogates helps you continually enhance your process efficiency. See how you can manage multiple plants from anywhere.

HOW INTELLIFLUX BENEFITS YOU

Lower OPEX

IntelliFlux uses Machine Learning, Artificial Intelligence, and Engineering Models to optimize your plant, minimizing consumption of energy, cleaning water, and consumables. IntelliFlux will raise the overall productivity and efficiency of your operation, reducing waste and plant downtime.

Protect Against Upsets

IntelliFlux autonomously responds to sudden fluctuations and spikes in feed quality or other extraneous factors influencing the process, and can deploy suitable measures for protecting your plant. It protects the plant against sudden upsets, enhancing plant reliability, and securing your assets.

Intelligent Decision-making

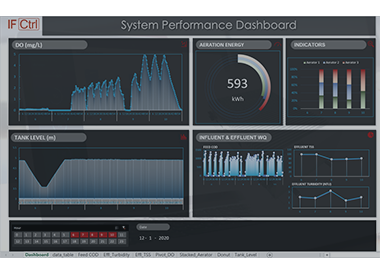

IntelliFlux constantly learns and develops plant specific operating knowledge that never leaves premises. It also provides daily and weekly automated performance reports utilizing advanced data analytics, giving you unprecedented insights into your plant performance, while freeing up operator reporting time.

EXPERIENCE CONTROL AS A SERVICE

Your Operation is Our Business

IntelliFlux monitors your process plant round the clock, converts data into insightful decisions and autonomous actions, resulting in improved

performance. Let IntelliFlux help enhance your operations with our digitalization solutions. We are experts at optimizing and improving your plant operations.

See how simple it is to convert your process plant into a "smart plant" with IntelliFlux.

in Your Savings

DELIVERING VALUE WITH SMARTNESS

Our results continue to impress our global clientele, helping them reduce

Energy

up to 50%

Consumables

up to 80%

Waste

up to 75%

OpEx

up to 40%

Target Industries

Digital transformation is changing every industry. With IntelliFlux, you can experience digitalization in two weeks time with no disruption of your current operations.

You are probably contemplating the risks of implementation, scale of deployment, benefits, and return on investment.

See how IntelliFlux is transforming operational practices in different chemical process industry verticals:

See how IntelliFlux is improving the efficiency of operation in upstream produced water treatment.

See how IntelliFlux is managing water treatment processes.

See how IntelliFlux is reducing waste water discharge from beverage production plants.

See how IntelliFlux is reducing the water footprint in textile and dyeing and processing.

AWARD WINNING TECHNOLOGY

Finalist

2018 Accelerator

Imagine H2O

Winner

Technology Idol

Global Water Intelligence

news

Contact us for a demonstration of our software today

We would love to hear from you to discuss how IntelliFlux can help your existing or upcoming chemical process plant, facility, or system.