You can be in control from anywhere, anytime..

EmpowerING our customers to be in control of their operations from anywhere, anytime

What We Do

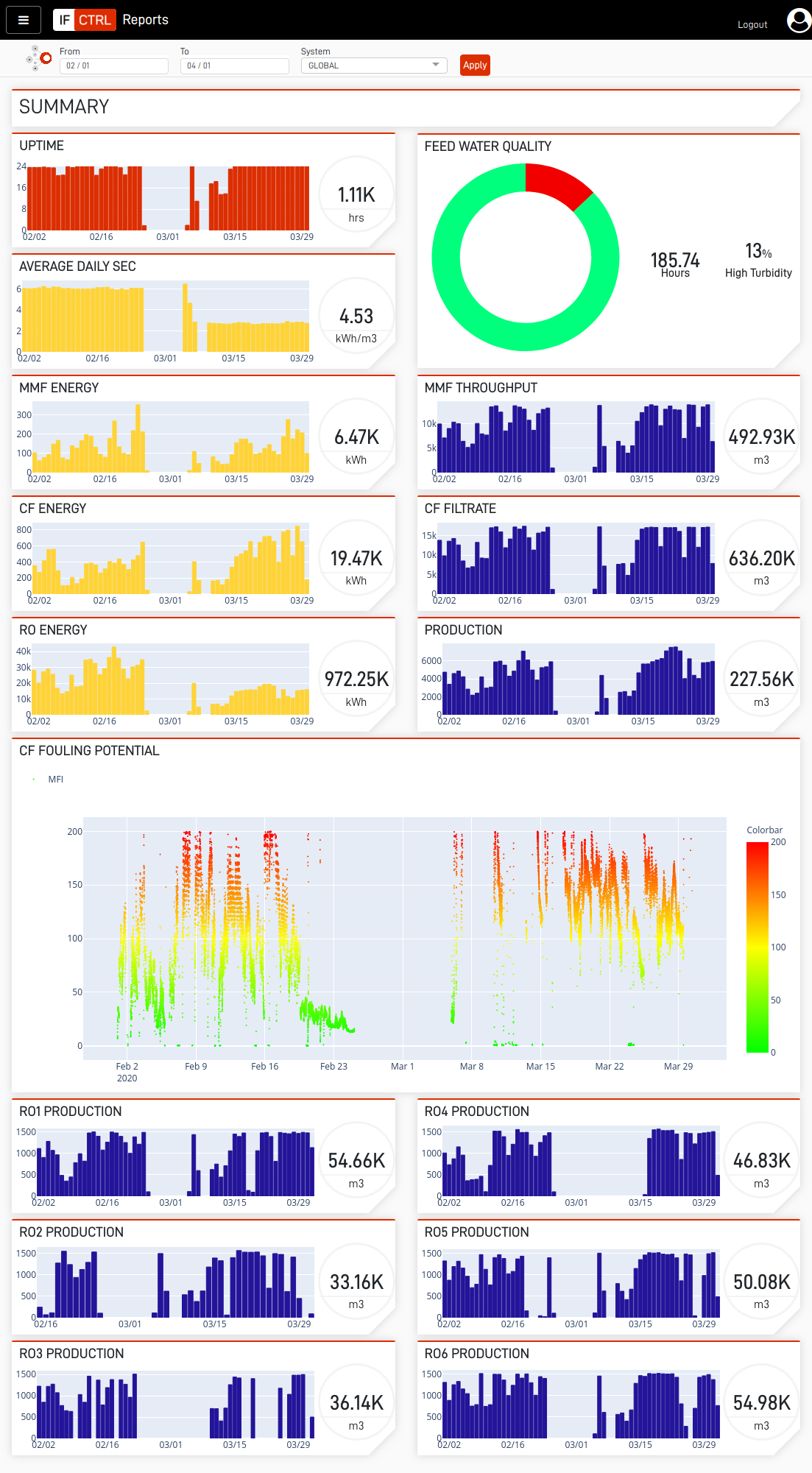

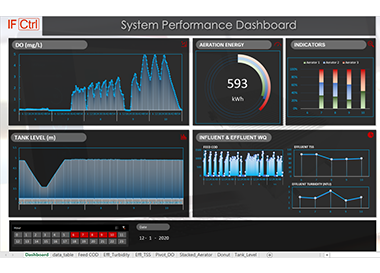

We implement automation retrofits to existing process plants that serve as virtual operator assistants, empowering the plant owner and operator to achieve dynamic plant optimization, energy and resource savings, compliance, asset & risk management, and sustainable operation.

IntelliFlux specializes in process control of individual technologies deployed in water treatment, chemical processing, and industrial separations plants. Through our experience in system and plant integration, we filled a major gap between how process engineers design and envision the control philosophy, and how the automation control logic is actually programmed at these plants. To address this gap systematically, we developed an approach that would apply the designed process dynamics to the control architecture, implement complex control strategies (such as MIMO, optimal control, adaptive control), as well as learn from the process behavior. This unique blend of digital replica and machine learning makes IntelliFlux a radically different, efficient, and effective approach to process automation. And, by retrofitting existing plants in a completely hardware agnostic manner, we have time and again shown our customers the true potential of their process plants, and how much of that value they can recapture with a software solution.

Who We Are

We are a systems engineering company that harnesses the engineering and process operations skills of a multidisciplinary team of engineers and software specialists to synergistically learn about the design and operation of process plants. With this knowledge embedded in our automation software and plant management services, we help plant owners and operators achieve smooth, reliable, and optimal operation. Applying self-learning automation to process plants has worked because we brought three key engineering disciplines together in one company: expertise in process technologies and their operation, cutting edge innovation in software, and deep experience in plant automation.

Key Numbers

60+ years of process technology expertise in the team

Operating continuously for over two years at multiple plants.

Operating globally with installations in seven countries

Customers

We serve customers from multiple processing industry sectors across the world. In many cases, we manage operations of multiple assets of a single client.